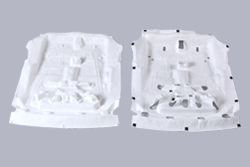

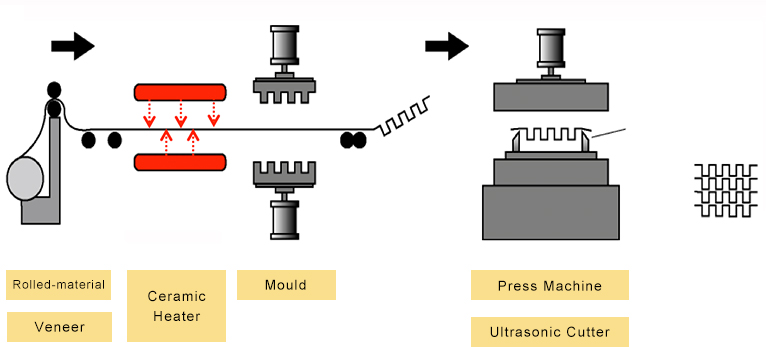

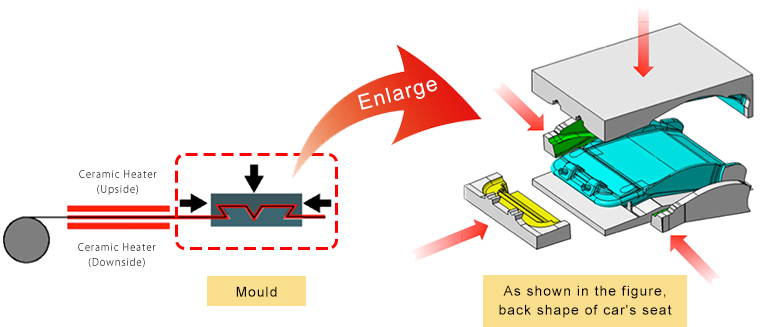

Mold

Continuous Vacumed Mold

Whether the material of mold products is thick or not(denstity between 100-2000g/㎡), we can produce at a low cost.

※ Mold and produce products with the size of 1,200mm×1,600mm

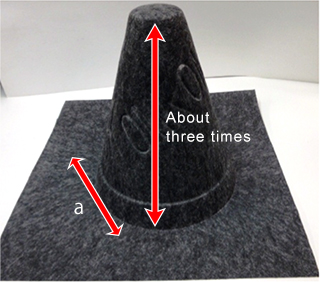

Continuous Vacumed Mold: Reverse drawing with all-around(peculiarity)

To welly control resilience amount of stamping parts in order to avoid shape’s resilience after demold.

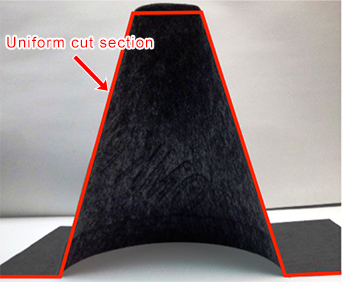

Deep-drawing Mold Process with uniform thickness

Usually, material will be thinner or be broken during the process of deep drawing, but we can make thickness be average.

Mold and produce different kinds of materials

We mainly press nonwovens, and also can press plastic, film and other hot plasticity material, skin material.

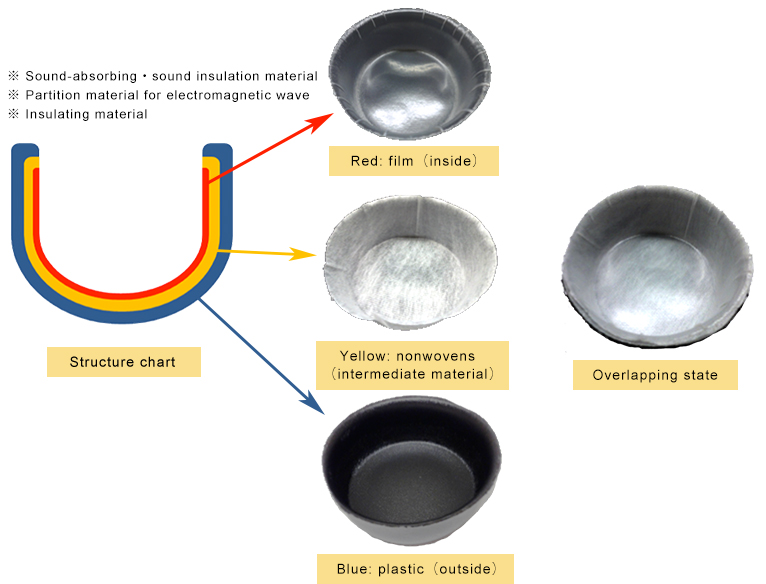

Compound(multilayer) press

By using different materials, the processed products can have different functions.

We put forward suitable processing proposals according to different requests and provide mold processing.

Lamination

Compound lamination

Laminate using rubber latex paste with water solubility.

Pick up different materials to laminate ,according to different uses.

Besides, provide processing proposals for different kinds of materials.

| ・Car(car’s interior decoration) |

| ・Office chairs(backs・seats trim cover) |

| ・Groceries (bags’and shoes’intermediate materials) |

| ・Clothes(clothes、underwears) |

| ・Construction materials (flooring sound-absorbing materials) |

| ・Others |

| Characters |

|---|

| ・Produce small batches of product(50m-) |

| ・Use Water-soluble adhesives with high security |

| Standards | |

|---|---|

| Effective Width | 1550mm(Highest Precision) |

| Adhesive | General or Flame-retarded Adhesive |

| Design Instruction | |

|---|---|

| 1 Lamination | 2 layers |

| 2 Laminations | 3 layers |

| Material | |

|---|---|

| Polyurethane | Thickness: about 2-20mm |

| Besides polyurethane | there are nonwovens、hosiery、resin cotton、film and so on. |

Cut、sew

Digitalization of product’s shape

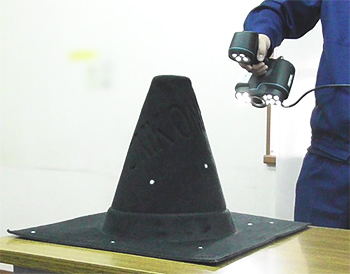

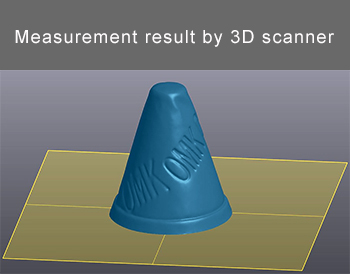

3D scanner

Using portable 3D scanner with light weight and small size, which can easily measure and calculate cubic shape of products and models, even in customer site.Besides,it can analyse and process the date automatically, and apply the date to make models.

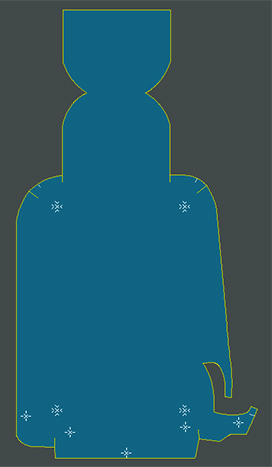

Digital Instrument

Using digital instrument can transform flat shape of cutting products and other products into data. The transformed data can be transmited and be applied to cutting production.